Brake Rotor Thickness Chart

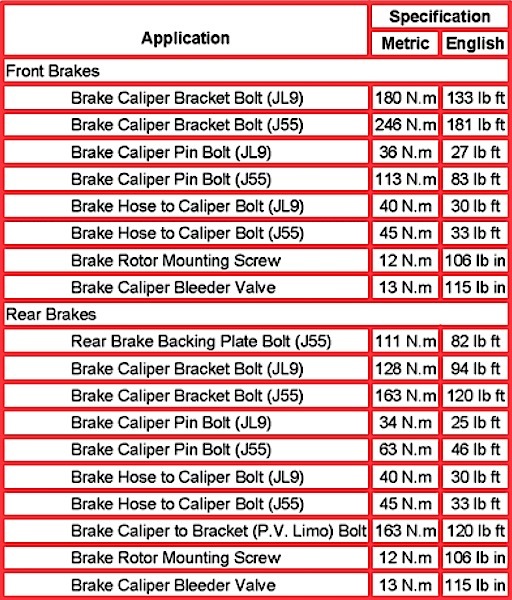

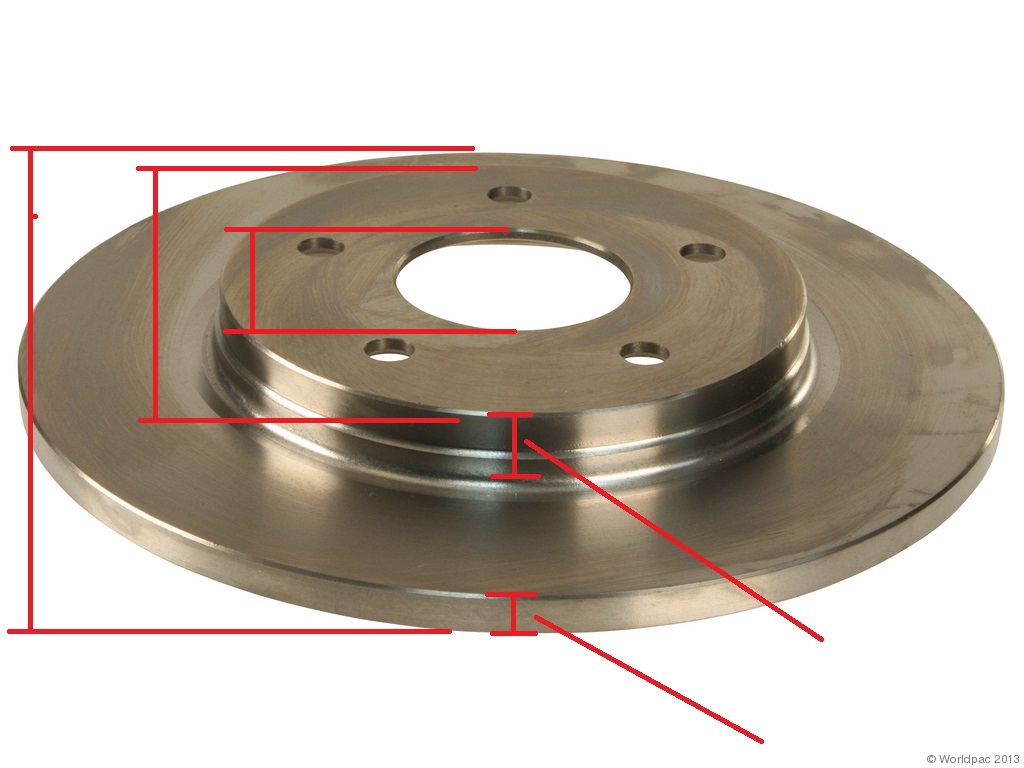

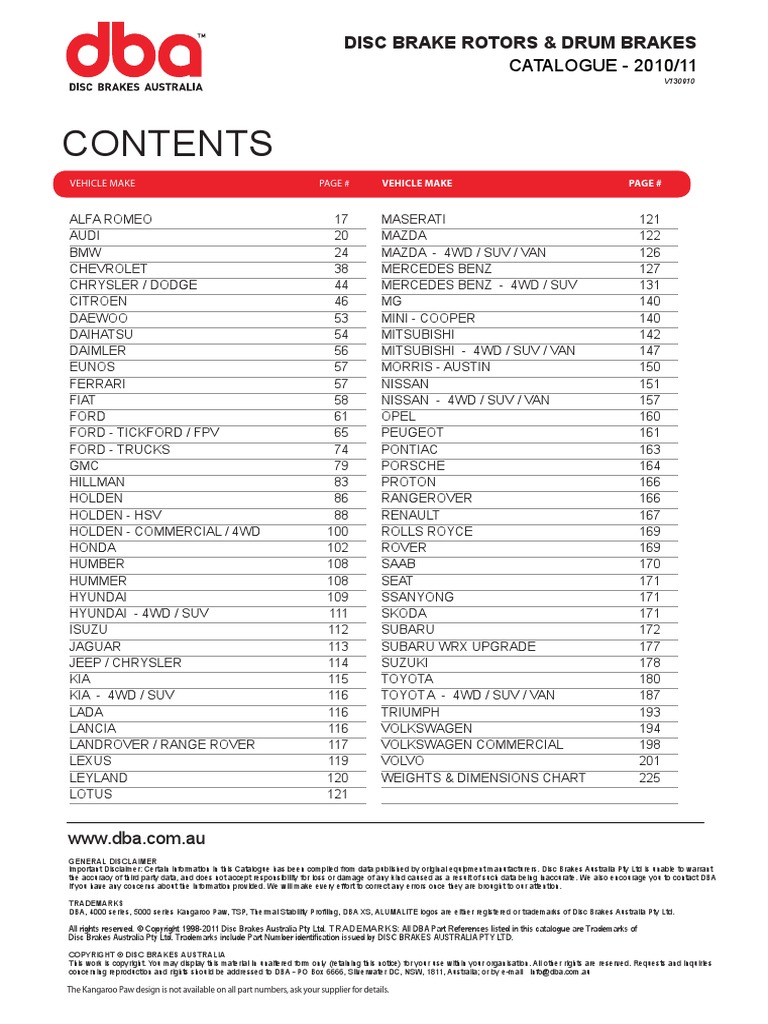

Brake Rotor Thickness Chart - Web measuring brake rotor thickness is a vital maintenance task that ensures your braking system remains effective and safe. This section usually contains a chart indicating all. Web follow specific steps and guidelines to accurately measure rotor thickness using a micrometer. Web mastering the art of reading brake rotor thickness gauges empowers you to maintain a safe and reliable braking system. If your rotor has worn past this thickness or needs to be cut, you need new rotors. The thicker the rotor, the more stopping power it has. Proper measurement can help you determine if your rotors need replacing, preventing potential brake failure. Web the minimum thickness for general inspection (motor vehicle inspection) is defined as follows: Web to measure your rotor’s minimum operational thickness, place a micrometer at the thinnest point on the rotor’s surface where it meets the brake pads. Web to measure the minimum brake rotor thickness correctly, you will need to use a gauge. Nominal size thickness minus 1.6 mm. Regularly measuring brake rotor wear is important to maintain braking efficiency and avoid costly consequences. The lowest value should be used as reference for the entire rotor. As shown here in figure 1 the base brake article contains a section titled technical specifications. Web mastering the art of reading brake rotor thickness gauges empowers you to maintain a safe and reliable braking system. Web how to choose the right thickness of the rotors of your vehicle. The thicker the rotor, the more stopping power it has. Adhere to minimum rotor thickness specifications, avoiding measurement near edges, slots, or holes. Web the 3 types of brake rotor thickness specs are: Proper measurement can help you determine if your rotors need replacing, preventing potential brake failure. Web most specifications for rotor thickness are found in the “base brake” articles. Your rotor may exhibit signs of disc thickness variation (dtv). The lowest value should be used as reference for the entire rotor. If your rotor has worn past this thickness or needs to be cut, you need new rotors. Web how to choose the right thickness of. This section usually contains a chart indicating all. Web measuring brake rotor thickness is a vital maintenance task that ensures your braking system remains effective and safe. As shown here in figure 1 the base brake article contains a section titled technical specifications. Measurements should be taken in at least 4 different points. Adhere to minimum rotor thickness specifications, avoiding. Regularly measuring brake rotor wear is important to maintain braking efficiency and avoid costly consequences. The thickness of the rotor is one factor that determines how well your vehicle will stop in a hurry. The lowest value should be used as reference for the entire rotor. Your rotor may exhibit signs of disc thickness variation (dtv). Adhere to minimum rotor. Web most specifications for rotor thickness are found in the “base brake” articles. Web to measure the minimum brake rotor thickness correctly, you will need to use a gauge. As shown here in figure 1 the base brake article contains a section titled technical specifications. Web to measure your rotor’s minimum operational thickness, place a micrometer at the thinnest point. The thicker the rotor, the more stopping power it has. Web the minimum thickness for general inspection (motor vehicle inspection) is defined as follows: As shown here in figure 1 the base brake article contains a section titled technical specifications. Your rotor may exhibit signs of disc thickness variation (dtv). The thickness of the rotor is one factor that determines. Web most specifications for rotor thickness are found in the “base brake” articles. Measurements should be taken in at least 4 different points. Proper measurement can help you determine if your rotors need replacing, preventing potential brake failure. Web the minimum thickness for general inspection (motor vehicle inspection) is defined as follows: The thicker the rotor, the more stopping power. The thicker the rotor, the more stopping power it has. Web the minimum thickness for general inspection (motor vehicle inspection) is defined as follows: Proper measurement can help you determine if your rotors need replacing, preventing potential brake failure. The lowest value should be used as reference for the entire rotor. Regularly measuring brake rotor wear is important to maintain. By following the steps outlined in this guide, you can confidently interpret readings , ensuring your rotors meet specifications and your vehicle performs optimally. This section usually contains a chart indicating all. If your rotor has worn past this thickness or needs to be cut, you need new rotors. Web most specifications for rotor thickness are found in the “base. Adhere to minimum rotor thickness specifications, avoiding measurement near edges, slots, or holes. Measurements should be taken in at least 4 different points. Web how to choose the right thickness of the rotors of your vehicle. The lowest value should be used as reference for the entire rotor. Web the minimum thickness for general inspection (motor vehicle inspection) is defined. Measurements should be taken in at least 4 different points. Web the minimum thickness for general inspection (motor vehicle inspection) is defined as follows: Your rotor may exhibit signs of disc thickness variation (dtv). This section usually contains a chart indicating all. Web the 3 types of brake rotor thickness specs are: Regularly measuring brake rotor wear is important to maintain braking efficiency and avoid costly consequences. Web the minimum thickness for general inspection (motor vehicle inspection) is defined as follows: Web the 3 types of brake rotor thickness specs are: The thicker the rotor, the more stopping power it has. Web how to choose the right thickness of the rotors of your vehicle. Web to measure your rotor’s minimum operational thickness, place a micrometer at the thinnest point on the rotor’s surface where it meets the brake pads. Adhere to minimum rotor thickness specifications, avoiding measurement near edges, slots, or holes. If your rotor has worn past this thickness or needs to be cut, you need new rotors. Web mastering the art of reading brake rotor thickness gauges empowers you to maintain a safe and reliable braking system. By following the steps outlined in this guide, you can confidently interpret readings , ensuring your rotors meet specifications and your vehicle performs optimally. This section usually contains a chart indicating all. Web measuring brake rotor thickness is a vital maintenance task that ensures your braking system remains effective and safe. Proper measurement can help you determine if your rotors need replacing, preventing potential brake failure. Web most specifications for rotor thickness are found in the “base brake” articles. The thickness of the rotor is one factor that determines how well your vehicle will stop in a hurry. Web to measure the minimum brake rotor thickness correctly, you will need to use a gauge.How to check & replace your BMW front disc brakes and rotors Page 6

2006 chevy equinox brakes

Minimum Rotor Thickness Chart Ford Best Picture Of Chart

Ford F150 Minimum Brake Rotor Thickness Chart / How do you use the

Repair Guides Disc Brakes Brake Disc (rotor)

Brake Rotor Thickness Chart

How do you use the information on a brake rotor thickness chart

Brake rotor minimum thickness chart toyota

Rotor Minimum Thickness Chart

Edel friedlich Dump tektro bremsscheibe dicke Gasförmig Schreibmaschine

Your Rotor May Exhibit Signs Of Disc Thickness Variation (Dtv).

Web Follow Specific Steps And Guidelines To Accurately Measure Rotor Thickness Using A Micrometer.

Measurements Should Be Taken In At Least 4 Different Points.

The Lowest Value Should Be Used As Reference For The Entire Rotor.

Related Post: