Electrical Lug Torque Chart

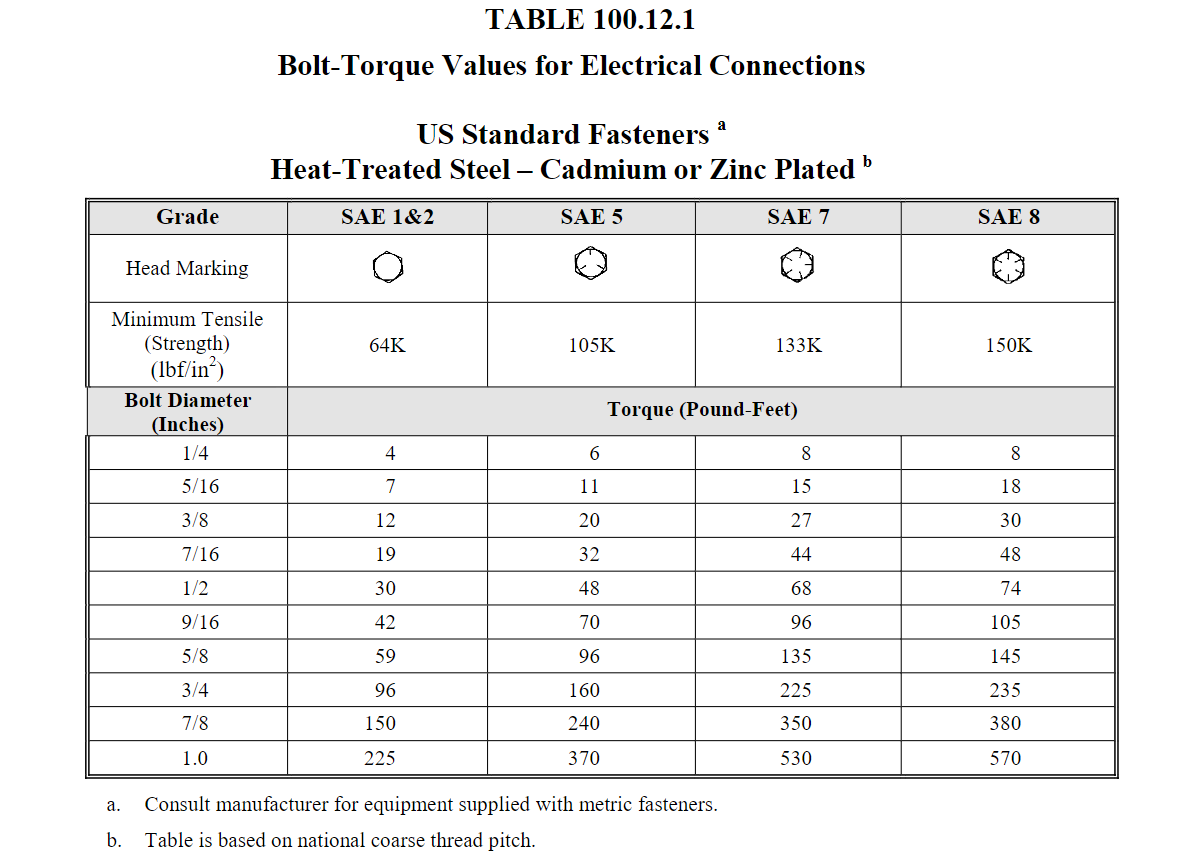

Electrical Lug Torque Chart - For lug with a tapped hole for control wire, add a “t”. Web proper torque is a figure recommended by the manufacturer of the terminal. The prevailing torque lock nut clamp loads are listed at 75% of the proof loads specified for the appropriate grade bolt: (a) bolts and nuts are new, standard finish, uncoated and not lubricated* (b) the load will. The rated clockwise tightening torque number on. It explains that the online library contains portable. • what data do we have in the industry and what do the connector standards If the threads of the lug are dry or not. Web in preparing this guide to torque values, the following basic assumptions have been made: Web faq guide on torque tightening technique and correct torque listings on ul and csa parts. If the threads of the lug are dry or not. See the actual nec ® text. Dwelling unit area reference chart for afci and gfci requirements. Web faq guide on torque tightening technique and correct torque listings on ul and csa parts. † conductors must be of equal size. Blue highlighted items are industry. Web connection torque values for main lug compartments and connection torque values for main and branch feeders provide main disconnect and branch feeder torque values,. Web this document provides information about torque values for electrical lugs and links to download related documents. For lug with a tapped hole for control wire, add a “t”. Web ses 75% of the yield strength. (a) bolts and nuts are new, standard finish, uncoated and not lubricated* (b) the load will. The rated clockwise tightening torque number on. Blue highlighted items are industry. • what data do we have in the industry and what do the connector standards The prevailing torque lock nut clamp loads are listed at 75% of the proof loads specified for. National electrical code introduction electrical connections. Blue highlighted items are industry. Web these lugs are attached to the main breaker with a flathead screw, and that doesn't seem quite strong enough to hold the lug while torquing. Web • what is torque at the engineering level and how does that translate to electrical connections? Web in the absence of connector. Web • what is torque at the engineering level and how does that translate to electrical connections? The rated clockwise tightening torque number on. In stock ready to shipfree shipping on $100+ For lug with a tapped hole for control wire, add a “t”. National electrical code introduction electrical connections. Web these lugs are attached to the main breaker with a flathead screw, and that doesn't seem quite strong enough to hold the lug while torquing. If the threads of the lug are dry or not. Web in the absence of connector or equipment manufacturer’s recommended torque values, table i.1, table i.2, and table i.3 may be used to correctly. The rated clockwise tightening torque number on. Web these lugs are attached to the main breaker with a flathead screw, and that doesn't seem quite strong enough to hold the lug while torquing. See the actual nec ® text. Web this document provides information about torque values for electrical lugs and links to download related documents. Web ses 75% of. Web listed torque values are for maximum conductor sizes accommodated. National electrical code introduction electrical connections. Web proper torque is a figure recommended by the manufacturer of the terminal. See the actual nec ® text. If the threads of the lug are dry or not. Blue highlighted items are industry. • what data do we have in the industry and what do the connector standards See the actual nec ® text. Below is a preview of the nec ®. The prevailing torque lock nut clamp loads are listed at 75% of the proof loads specified for the appropriate grade bolt: Web listed torque values are for maximum conductor sizes accommodated. Web in the absence of connector or equipment manufacturer’s recommended torque values, table i.1, table i.2, and table i.3 may be used to correctly tighten screw. Below is a preview of the nec ®. Web these lugs are attached to the main breaker with a flathead screw, and that doesn't. † conductors must be of equal size. Web faq guide on torque tightening technique and correct torque listings on ul and csa parts. Web in the absence of connector or equipment manufacturer’s recommended torque values, table i.1, table i.2, and table i.3 may be used to correctly tighten screw. Web connection torque values for main lug compartments and connection torque. For lug with a tapped hole for control wire, add a “t”. But then consider a copper/aluminum lug. National electrical code introduction electrical connections. See the actual nec ® text. Blue highlighted items are industry. Web • what is torque at the engineering level and how does that translate to electrical connections? Fast shippingexplore amazon devicesshop our huge selectiondeals of the day Web connection torque values for main lug compartments and connection torque values for main and branch feeders provide main disconnect and branch feeder torque values,. • what data do we have in the industry and what do the connector standards Dwelling unit area reference chart for afci and gfci requirements. 4.5/5 (1,511 reviews) Web these lugs are attached to the main breaker with a flathead screw, and that doesn't seem quite strong enough to hold the lug while torquing. † conductors must be of equal size. Web proper torque is a figure recommended by the manufacturer of the terminal. If the threads of the lug are dry or not. Web listed torque values are for maximum conductor sizes accommodated.Electrical Lug Torque Specs Chart Siemens

Wire Lug Torque Specs Chart

Nec Electrical Lug Torque Specs Chart

Nec Electrical Lug Torque Specs Chart Printable Templates Free

Nec Electrical Lug Torque Specs Chart

Nec Electrical Lug Torque Specs Chart

Electrical Lug Torque Specs Chart Square D

Electrical Lug Torque Chart

Electrical Lug Torque Specs Chart Eaton

Web Ses 75% Of The Yield Strength.

Web Listed Torque Values Are For Maximum Conductor Sizes.

Below Is A Preview Of The Nec ®.

Web In Preparing This Guide To Torque Values, The Following Basic Assumptions Have Been Made:

Related Post: