Metal Roofing Gauge Chart

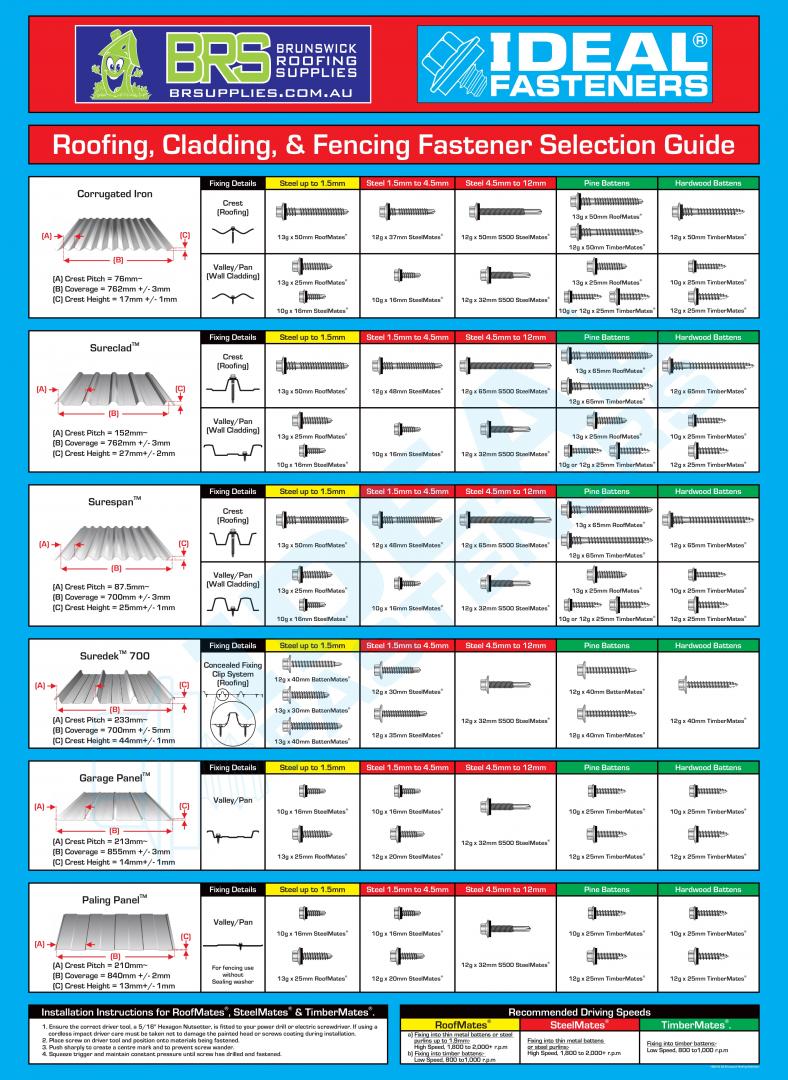

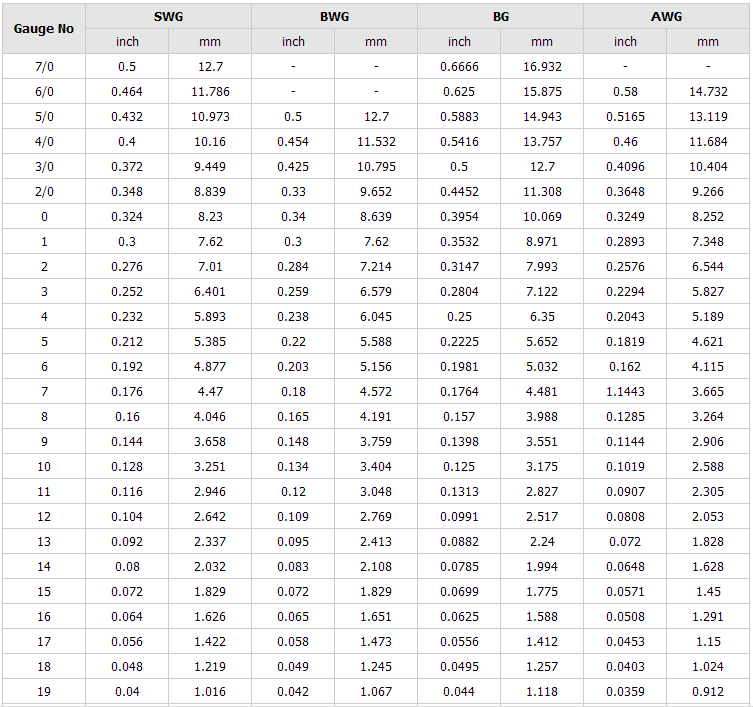

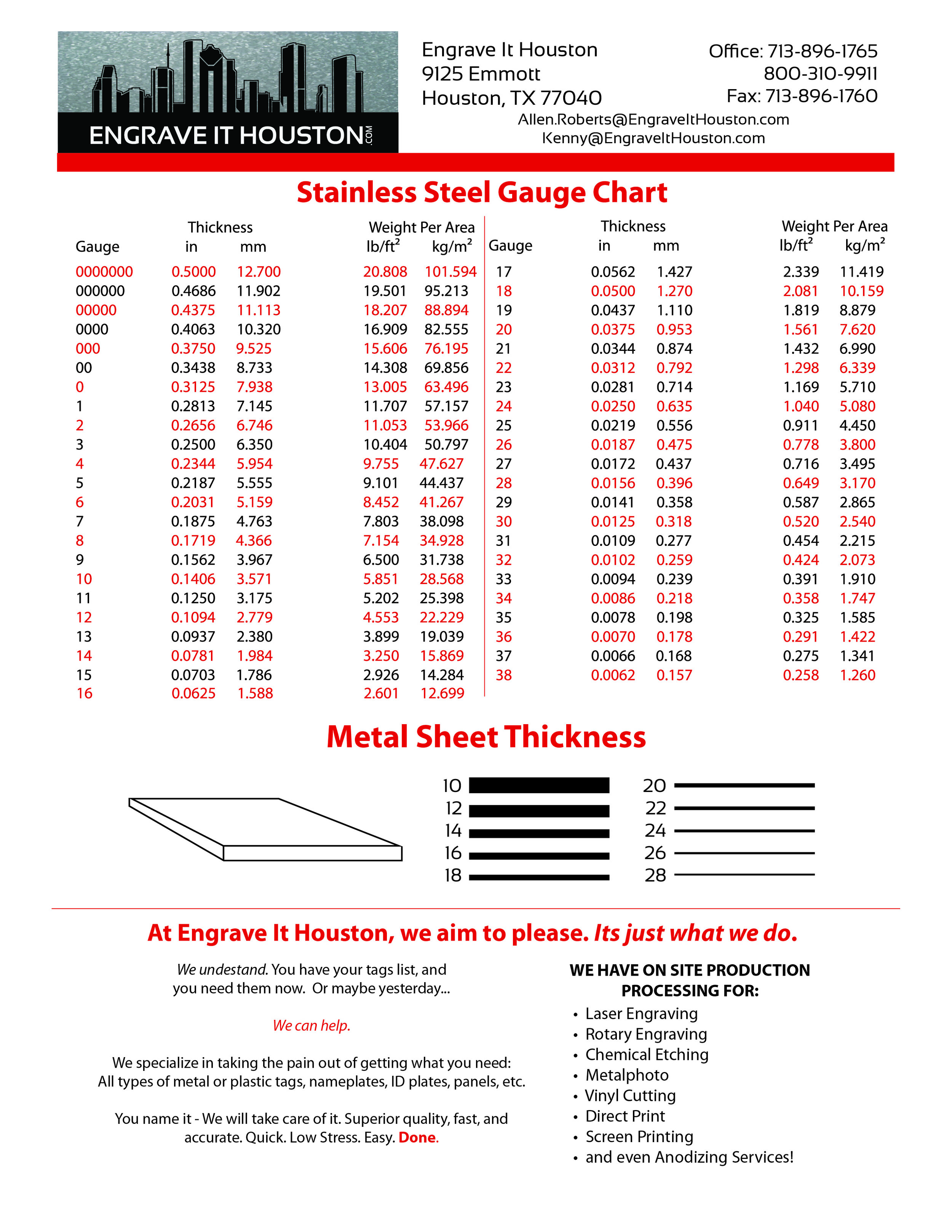

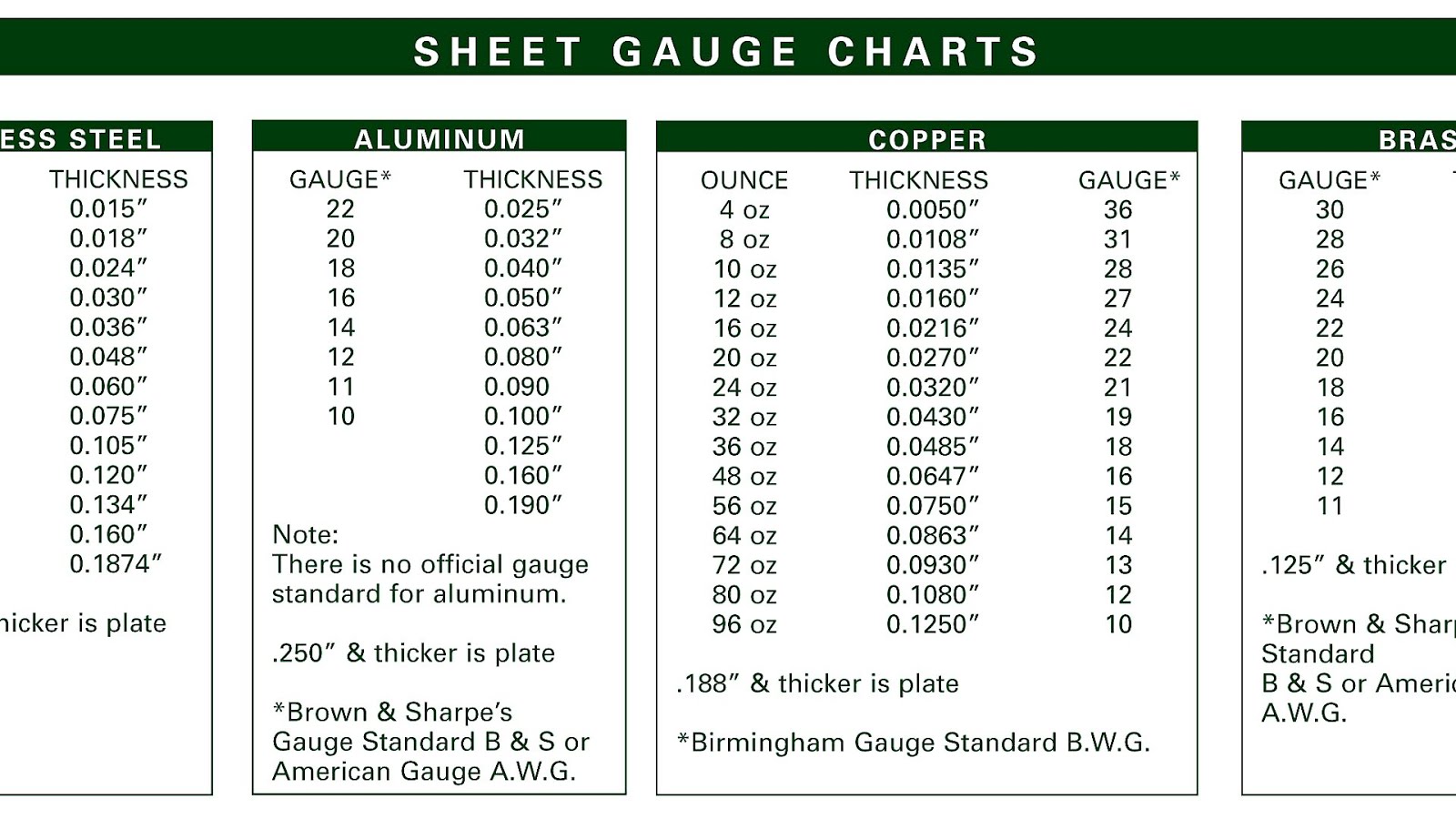

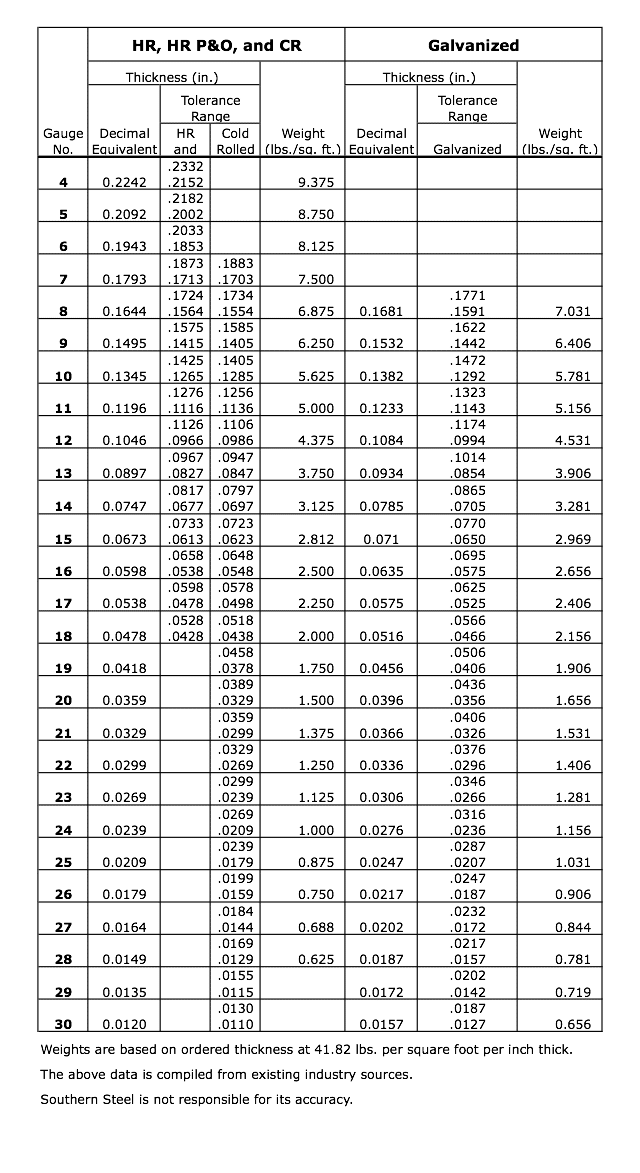

Metal Roofing Gauge Chart - Web the most popular options are 22, 24, 26, and 29. Web the most common gauges you’ll find are 22, 24, 26, and 29, with each having unique characteristics, advantages, and potential challenges. By understanding the nuances of. Roof panels vary in thickness from 22 gauge to 29 gauge. Out of these four gauges, 24 gauge and 26 gauge are the most widely used. Web looking for the correct gauge for your corrugated metal roof? Thicker gauges offer more durability and resistance to elements. Web the gauge of metal roofing you should use depends on your needs. Web manufacturers in the united states use gauge to express the thickness of metal roof panels. Where you’re located, your building’s structure, your area’s climate, and more are all factors. Roof panels vary in thickness from 22 gauge to 29 gauge. Web the most common gauge sizes for metal roofing are 22, 24, 26, and 29. Web manufacturers in the united states use gauge to express the thickness of metal roof panels. There are pros and cons to each. Web the most common gauges you’ll find are 22, 24, 26, and 29, with each having unique characteristics, advantages, and potential challenges. Web the most popular options are 22, 24, 26, and 29. Web common gauges for steel roofing range from 22 to 29 gauge, with 29 being thinner and 22 being thicker. Where you’re located, your building’s structure, your area’s climate, and more are all factors. Web looking for the correct gauge for your corrugated metal roof? Thicker gauges offer more durability and resistance to elements. Where you’re located, your building’s structure, your area’s climate, and more are all factors. Web common gauges for steel roofing range from 22 to 29 gauge, with 29 being thinner and 22 being thicker. There are pros and cons to each. Web the most popular options are 22, 24, 26, and 29. By understanding the nuances of. Web the most common gauge sizes for metal roofing are 22, 24, 26, and 29. Web looking for the correct gauge for your corrugated metal roof? Out of these four gauges, 24 gauge and 26 gauge are the most widely used. Web the gauge of metal roofing you should use depends on your needs. There are pros and cons to. Web the most common gauges you’ll find are 22, 24, 26, and 29, with each having unique characteristics, advantages, and potential challenges. Web the most common gauge sizes for metal roofing are 22, 24, 26, and 29. Out of these four gauges, 24 gauge and 26 gauge are the most widely used. Web the gauge of metal roofing you should. There are pros and cons to each. Where you’re located, your building’s structure, your area’s climate, and more are all factors. We discuss how metal gauge affects installation and compare the different gauges. Web common gauges for steel roofing range from 22 to 29 gauge, with 29 being thinner and 22 being thicker. Web looking for the correct gauge for. Web the most popular options are 22, 24, 26, and 29. Where you’re located, your building’s structure, your area’s climate, and more are all factors. Web the gauge of metal roofing you should use depends on your needs. Web common gauges for steel roofing range from 22 to 29 gauge, with 29 being thinner and 22 being thicker. There are. Thicker gauges offer more durability and resistance to elements. There are pros and cons to each. By understanding the nuances of. We discuss how metal gauge affects installation and compare the different gauges. Web manufacturers in the united states use gauge to express the thickness of metal roof panels. Web the gauge of metal roofing you should use depends on your needs. Out of these four gauges, 24 gauge and 26 gauge are the most widely used. Web looking for the correct gauge for your corrugated metal roof? Where you’re located, your building’s structure, your area’s climate, and more are all factors. Web the most common gauge sizes for. Web looking for the correct gauge for your corrugated metal roof? Web the most popular options are 22, 24, 26, and 29. Thicker gauges offer more durability and resistance to elements. Where you’re located, your building’s structure, your area’s climate, and more are all factors. There are pros and cons to each. Where you’re located, your building’s structure, your area’s climate, and more are all factors. Web looking for the correct gauge for your corrugated metal roof? Web manufacturers in the united states use gauge to express the thickness of metal roof panels. There are pros and cons to each. Web the most common gauges you’ll find are 22, 24, 26, and. Out of these four gauges, 24 gauge and 26 gauge are the most widely used. Web manufacturers in the united states use gauge to express the thickness of metal roof panels. Web looking for the correct gauge for your corrugated metal roof? Roof panels vary in thickness from 22 gauge to 29 gauge. Web common gauges for steel roofing range. Web manufacturers in the united states use gauge to express the thickness of metal roof panels. There are pros and cons to each. Web the most common gauge sizes for metal roofing are 22, 24, 26, and 29. We discuss how metal gauge affects installation and compare the different gauges. Web the most common gauges you’ll find are 22, 24, 26, and 29, with each having unique characteristics, advantages, and potential challenges. Web the most popular options are 22, 24, 26, and 29. Out of these four gauges, 24 gauge and 26 gauge are the most widely used. Web looking for the correct gauge for your corrugated metal roof? By understanding the nuances of. Web common gauges for steel roofing range from 22 to 29 gauge, with 29 being thinner and 22 being thicker. Web the gauge of metal roofing you should use depends on your needs.Metal Roofing Gauge Conversion Chart

Metal Roofing Gauge Chart

Metal Roofing Gauge Chart

Understanding Metal Roofing Gauges A Comprehensive Guide

Metal Roofing Gauge Chart

Stainless Steel Gauges Chart

Metal Roof Gauge Chart

Metal Roof Gauge Thickness Chart

Metal Roofing Gauge Chart

Sheet Metal Gauge Thickness Chart All Points Fasteners

Roof Panels Vary In Thickness From 22 Gauge To 29 Gauge.

Thicker Gauges Offer More Durability And Resistance To Elements.

Where You’re Located, Your Building’s Structure, Your Area’s Climate, And More Are All Factors.

Related Post: