Mig Wire Size Chart

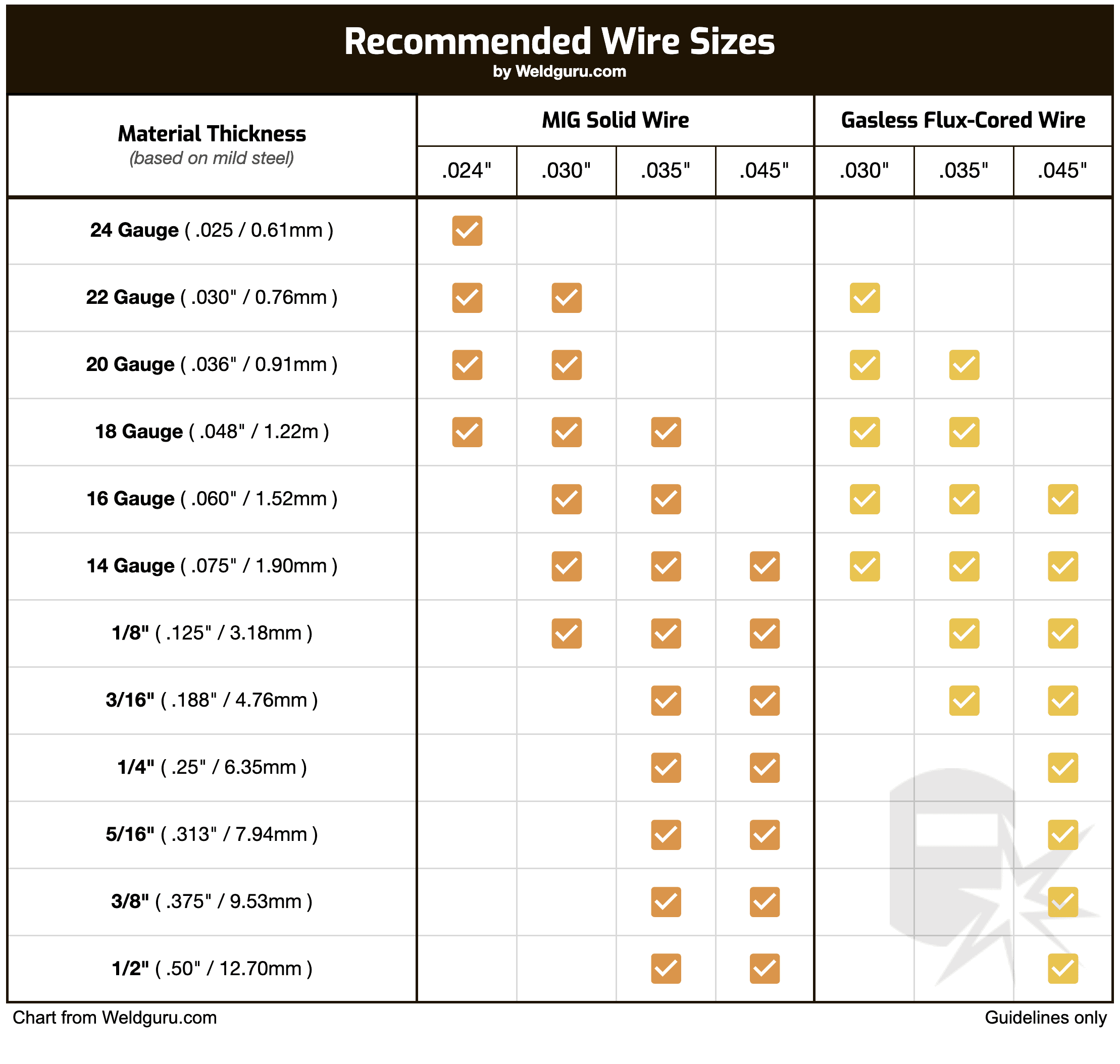

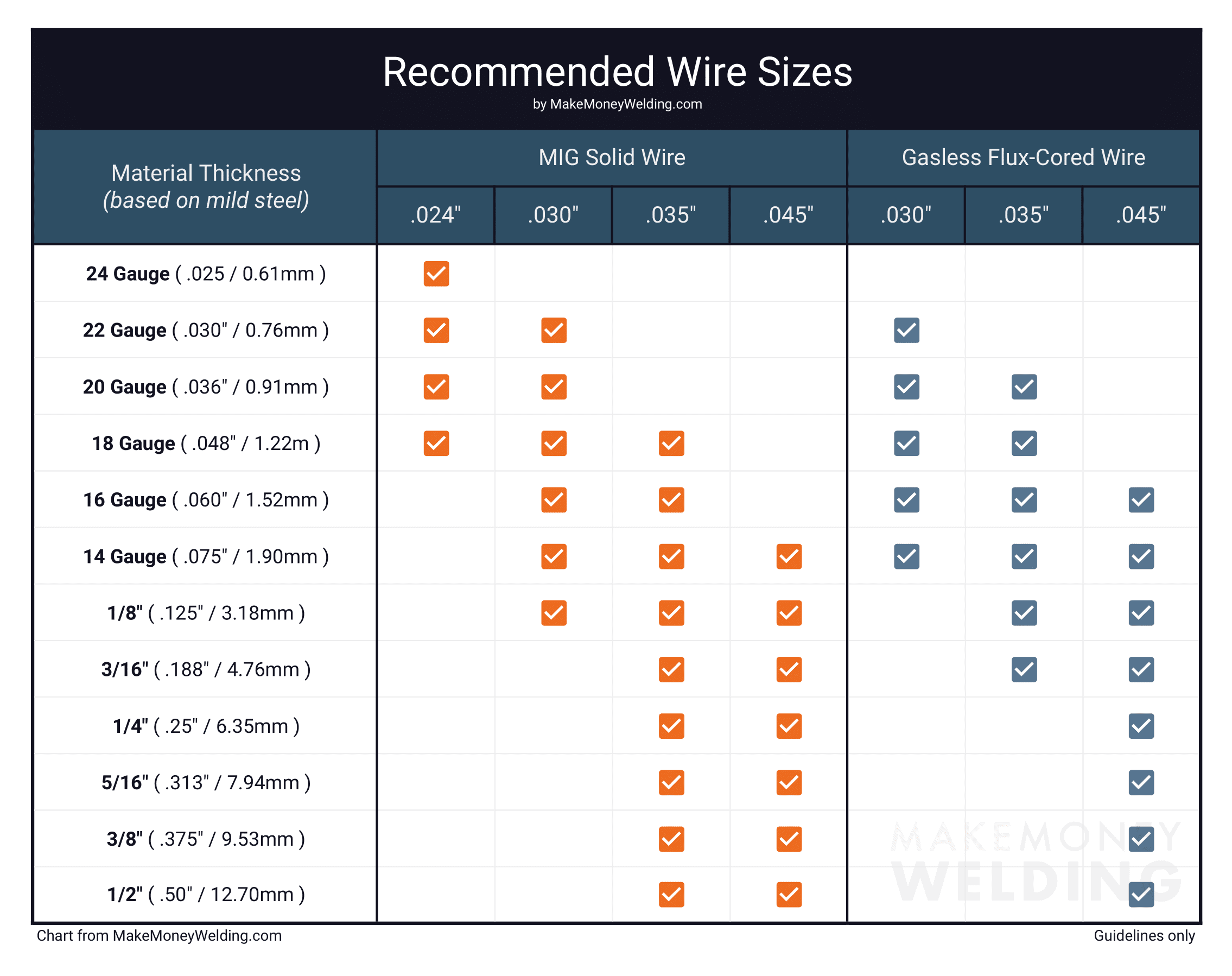

Mig Wire Size Chart - For thicker materials use a larger wire diameter and larger machine, check the recommended welding capability. Web quick guide for selecting mig wire size and welder amperage for your application. Besides, the welding process will not wipe out their bank accounts. Web esab's mig wire selection guide will help you make the right choice for the types of welds you want to make and the machines in your shop. Web for example, when welding sheet metal, the most common wire sizes are 0.35 and 0.45 inches. Check with your machine manufacturer for any information that may pertain to your welding system. Covering classifications, refrence charts and gas choices. Web mig wire chart. Choosing the right type of mig wire is critical for the look and strength of the welds you create. How to choose the right mig wire for a good weld strength. How to choose the right mig wire for a good weld strength. Plus, don’t miss my tips that make the task of mig welding aluminum not only achievable but also efficient. After all, this type of welding works great with such materials. In some cases, it will depend on the kind of welding machine you’re using and in others, it will depend on the method. Web select proper wire size according to amperage. Besides, the welding process will not wipe out their bank accounts. If the wire is to thin for the material thickness it will be difficult to weld. The contact tip recess is a measurement of the position that the contact tip takes within the nozzle. Aluminum mig welding settings chart. Click image for a larger view. Web select proper wire size according to amperage. Numbers might be slightly off when setting up your welding machine but you will get the general fell after a few tries. Use stainless steel wire for stainless steel, aluminium wires for aluminium and steel wires for steel. How to choose the right mig wire for a good weld strength. For thicker. Click image for a larger view. Choosing the right type of mig wire is critical for the look and strength of the welds you create. How to choose the right mig wire for a good weld strength. In some cases, it will depend on the kind of welding machine you’re using and in others, it will depend on the method.. However, when welding thin steel, you’ll probably need a solid mig wire with a smaller diameter, either 0.24 or 0.30 inches. Numbers might be slightly off when setting up your welding machine but you will get the general fell after a few tries. For thicker materials use a larger wire diameter and larger machine, check the recommended welding capability. We. Besides, the welding process will not wipe out their bank accounts. For most welders, mig welding is ideal for several types of metal including aluminum. For thicker materials use a larger wire diameter and larger machine, check the recommended welding capability. In some cases, it will depend on the kind of welding machine you’re using and in others, it will. Choosing the right type of mig wire is critical for the look and strength of the welds you create. Since you don't want to change wire, select one for your most commonly used thicknesses. Web on a mig welding contact tip sizing chart, you will notice a column that says “recess/extension.” understanding this measurement is crucial for being able to. Web on a mig welding contact tip sizing chart, you will notice a column that says “recess/extension.” understanding this measurement is crucial for being able to pick out the right contact tip for your work, although it is often an overlooked factor. Aluminum mig welding settings chart. Knowing how much wire is on a mig spool is useful to determine. For most welders, mig welding is ideal for several types of metal including aluminum. Web on a mig welding contact tip sizing chart, you will notice a column that says “recess/extension.” understanding this measurement is crucial for being able to pick out the right contact tip for your work, although it is often an overlooked factor. If the wire is. Web in this blog post, we will explore the key factors that affect mig welding sheet metal, including wire size, gas selection, amperage, and voltage. Knowing how much wire is on a mig spool is useful to determine how much mig welding wire to buy, this guide will help you! Click image for a larger view. Check with your machine. Aluminum mig welding settings chart. Below is a full chart of recommended wire sizes based on the thickness of the welded material: Web from detailed settings charts that guide you through the intricate world of voltage, amperage, and wire feed speed, to a breakdown of the best aluminum mig wire for various applications, i’ve got you covered. Why are there. How to choose the right mig wire for a good weld strength. There are many mig setting charts available from manufacturers that all vary. After deciding your wire spool classification, you must identify its diameter to work it accordingly. Web mig welding electrode wire selection guide for carbon steel, stainless steel and aluminum alloys. For thicker materials use a larger. Web from detailed settings charts that guide you through the intricate world of voltage, amperage, and wire feed speed, to a breakdown of the best aluminum mig wire for various applications, i’ve got you covered. There are various criteria to consider when setting your mig weld controls, including materials, metal thickness, shielding gas, electrode wires, and amperage. The contact tip recess is a measurement of the position that the contact tip takes within the nozzle. Numbers might be slightly off when setting up your welding machine but you will get the general fell after a few tries. We will also provide a mig wire size chart to help you select the appropriate wire size for your welding project. Covering classifications, refrence charts and gas choices. Web mig wire chart. Web a mig wire size chart provides recommended wire diameters for different metal thicknesses. Web mig welding electrode wire selection guide for carbon steel, stainless steel and aluminum alloys. For thicker materials use a larger wire diameter and larger machine, check the recommended welding capability. Plus, don’t miss my tips that make the task of mig welding aluminum not only achievable but also efficient. Why are there different wire diameters? In making a mig wire purchase, your last decision involves the quantity of wire and how it’s housed. Below is a full chart of recommended wire sizes based on the thickness of the welded material: Web esab's mig wire selection guide will help you make the right choice for the types of welds you want to make and the machines in your shop. Web the welding wire size chart is a crucial guide for selecting the right welding wire size, which varies according to material thickness and type of welding.welding cable size chart pdf Wiring Diagram and Schematics

Welders Discount Warehouse, , STAINLESS STEEL 309 MIG WIRE

Airgas

MIG Welding Tricks, Tips, and Proper Techniques Custom Classic Trucks

MIG Wire — Welspring Universal

mig wire selection Grumpys Performance Garage

W252 UNIMIG 390 Compact Industrial MIG Welder Hare & Forbes

MIG & Flux Core Welding Wire Types & Specification (with Chart) Weld Guru

How To MIG Weld Aluminum Beginners Guide (with Chart)

MIG Welding Wire Essentials A Guide to Types & Uses

Click Image For A Larger View.

For Most Welders, Mig Welding Is Ideal For Several Types Of Metal Including Aluminum.

Choosing The Right Type Of Mig Wire Is Critical For The Look And Strength Of The Welds You Create.

Aluminum Mig Welding Settings Chart.

Related Post: