Tig Cup Size Chart

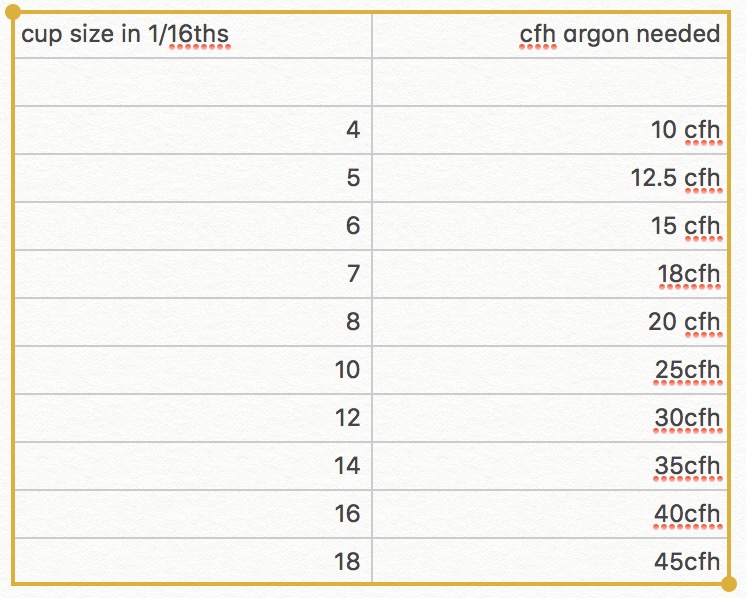

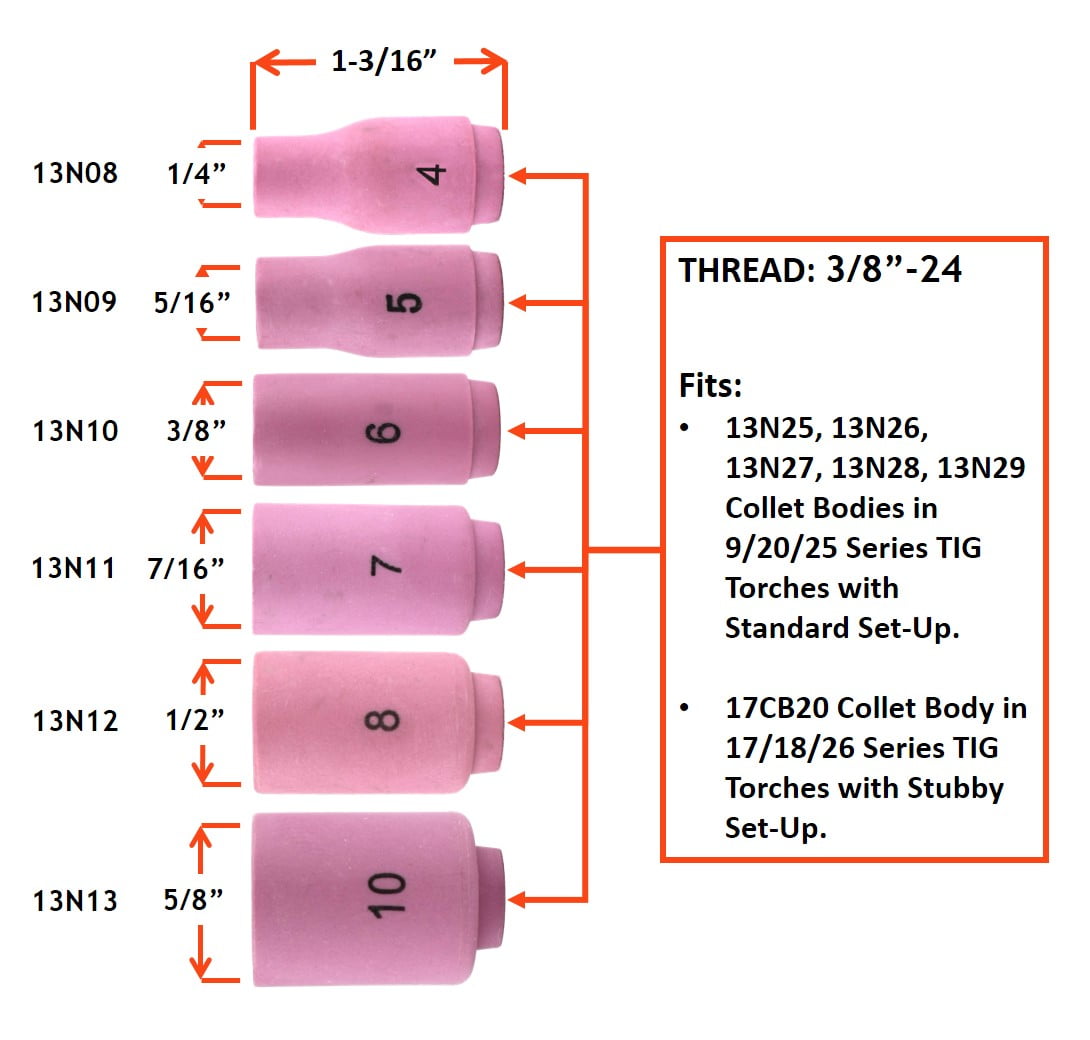

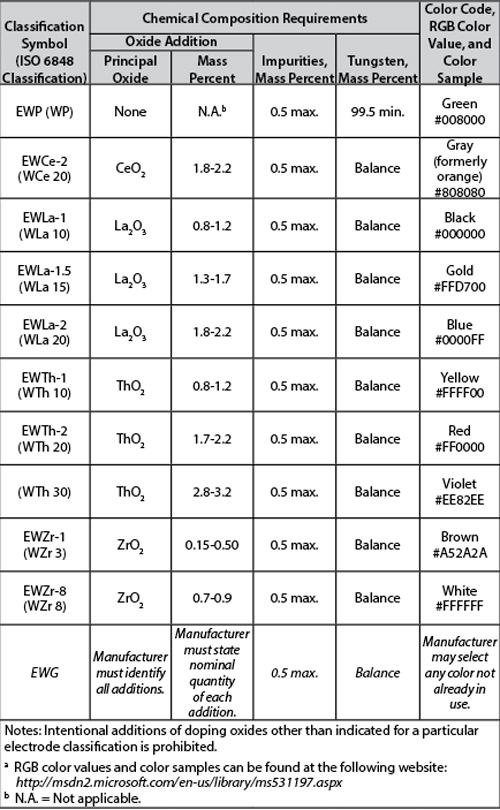

Tig Cup Size Chart - Web different cup sizes are often used for various metals, thicknesses, and purposes. I am using 3/32 tungsten and welding 1/8 steel. Direct current straight polarity (dcsp), direct current reverse polarity (dcrp), and alternating current with or without high frequency stabilization Choosing the correct size depends on material thickness, joint type, and desired weld bead profile. We need a lot less flow in tig welding. 3/8x 32 tungsten electrode conversion chart size suffix inches millimeters 20.020.5mm. Web tig torch cup size. Tungsten diameter and cup size. I am now trying #4. By russ (concord, nc) how do you determine the best cup size. Which cup works for which metal? 3 series (10n) torch models 17, 18, 26 thread pattern: Web which one works best? Web tig torch cup size. Choosing the correct size depends on material thickness, joint type, and desired weld bead profile. Web how do i choose a cup size for tig welding? 3/8x 32 tungsten electrode conversion chart size suffix inches millimeters 20.020.5mm. Web different cup sizes are often used for various metals, thicknesses, and purposes. In this article, we are going to look in detail at how you can select the correct cup size for your tig welding project. Web what metal are you welding? Web when tig welding, there are three choices of welding current. Direct current straight polarity (dcsp), direct current reverse polarity (dcrp), and alternating current with or without high frequency stabilization I am using 3/32 tungsten and welding 1/8 steel. We need a lot less flow in tig welding. In this article, we are going to look in detail at how. Adequate gas flow for gmaw typically ranges from 35 to 50 cubic feet per hour. In this article, we are going to look in detail at how you can select the correct cup size for your tig welding project. Web what metal are you welding? Which cup works for which metal? By russ (concord, nc) how do you determine the. Adequate gas flow for gmaw typically ranges from 35 to 50 cubic feet per hour. How do you set up your tig cup properly? Web which one works best? I am now trying #4. 3 series (10n) torch models 17, 18, 26 thread pattern: Selecting the appropriate cup size for tig welding is essential for achieving optimal results in your welding projects. 3/8x 32 tungsten electrode conversion chart size suffix inches millimeters 20.020.5mm. Choosing the correct size depends on material thickness, joint type, and desired weld bead profile. Web which one works best? Web what metal are you welding? Web what metal are you welding? Direct current straight polarity (dcsp), direct current reverse polarity (dcrp), and alternating current with or without high frequency stabilization I am using 3/32 tungsten and welding 1/8 steel. The cup size impacts gas coverage, heat tolerance, and the quality of the weld. Web tig torch cup size. I am now trying #4. 3 series (10n) torch models 17, 18, 26 thread pattern: Web this document outlines factors to consider when selecting proper cup size for tig welding and how to measure a cup size. The cup size impacts gas coverage, heat tolerance, and the quality of the weld. See the chart below for current ranges of all. In this article, we are going to look in detail at how you can select the correct cup size for your tig welding project. Web which one works best? By russ (concord, nc) how do you determine the best cup size. Web how do i choose a cup size for tig welding? Which cup works for which metal? Web cup sizes typically range from #4 (1/4 inch or 6.4 mm) to #12 (3/4 inch or 19 mm). Web this document outlines factors to consider when selecting proper cup size for tig welding and how to measure a cup size. In this article, we are going to look in detail at how you can select the correct cup size. The cup size impacts gas coverage, heat tolerance, and the quality of the weld. Adequate gas flow for gmaw typically ranges from 35 to 50 cubic feet per hour. Web how do i choose a cup size for tig welding? Tungsten diameter and cup size. Which cup works for which metal? Selecting the appropriate cup size for tig welding is essential for achieving optimal results in your welding projects. I am now trying #4. I started with a #7 as it came with the torch. We need a lot less flow in tig welding. How do you set up your tig cup properly? The cup size impacts gas coverage, heat tolerance, and the quality of the weld. I am using 3/32 tungsten and welding 1/8 steel. Web how do i choose a cup size for tig welding? 3 series (10n) torch models 17, 18, 26 thread pattern: Web what metal are you welding? Adequate gas flow for gmaw typically ranges from 35 to 50 cubic feet per hour. Web when tig welding, there are three choices of welding current. I am now trying #4. By russ (concord, nc) how do you determine the best cup size. Web cup sizes typically range from #4 (1/4 inch or 6.4 mm) to #12 (3/4 inch or 19 mm). For tig welding, common choices include #4 (1/4″), #5 (5/16″), #6 (3/8″), #7 (1/16″) and #8 (1/2″). Selecting the appropriate cup size for tig welding is essential for achieving optimal results in your welding projects. Web which one works best? Web tig torch cup size. Which cup works for which metal? In this article, we are going to look in detail at how you can select the correct cup size for your tig welding project.Tig Torch Sizes Chart

Tig Cup Size Chart

Tig Cup Size Chart

Alumina Nozzle Cups for TIG Welding Torches Series 9/20/25 with Gas Le

Tig Welding Cup Size Chart Best Picture Of Chart

Tig Welding Cup Size Chart Best Picture Of Chart

Tig Cup Size Chart

Anncus Welding Accessories TIG KIT Alumina Nozzle Cup 13N08 13N09 13N09

Tig Welding Cup Size Chart Best Picture Of Chart

Tig Welding Ceramic Cup Sizes Best Image Home

Browse Suggested Weld Parameter Settings For Tig Welding.

Web Different Cup Sizes Are Often Used For Various Metals, Thicknesses, And Purposes.

Choosing The Correct Size Depends On Material Thickness, Joint Type, And Desired Weld Bead Profile.

Web This Document Outlines Factors To Consider When Selecting Proper Cup Size For Tig Welding And How To Measure A Cup Size.

Related Post: